Hit enter to search or ESC to close

Product descriptions

In demand 510L 700L Hot Rolled Bridge Structural Steel Plate for Automobile beam steel

| PRODUCT NAME | Hot Rolled Bridge Structural Steel Plate for Automobile beam steel |

| THICKNESS | 1.5-20 mm |

| WIDTH | 30-5000 mm |

| STANDARD | GB/T 714,GB/T 19879,GB/T 3274,GB/T 912,JIS G3106,ASTM A572/A572M |

| Grade | 510L 700L |

| Surface | Mild steel surface, hot dip galvanized, color coated |

| Processing service | Provide Deep Processing Services |

| MOQ | 1 Tons |

Product Overview

High strength steel plate

High strength steel plate is an iron carbon alloy with a carbon content between 0.0218% and 2.11%, also known as carbon steel. It usually also contains small amounts of elements such as silicon, manganese, sulfur, and phosphorus. The performance of carbon steel plate mainly depends on its carbon content. The higher the carbon content, the greater the hardness and strength, but the plasticity

will decrease.

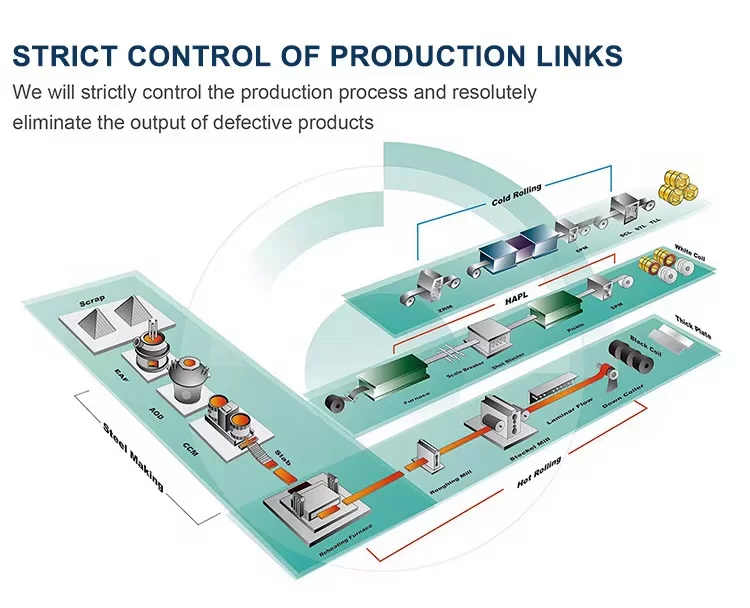

Product Processing and Product Testing

The processing methods of High strength steel plate include cutting, forming,heat treatment, polishing, spray painting, etc.

Preprocessing Before processing High strength steel plate, some pre-treatment work needs to be carried out on the plates. Firstly, it is necessary to perform surface drying treatment on the steel plate to remove surface moisture and oil stains, so as not to affect the next processing work. Secondly, it is necessary to conduct inspections, including visual inspection, dimensional inspection, and metallographic examination, to ensure that the quality of the steel plate meets the requirements.

Cutting Cutting is an important task in the processing of carbon steel plates. The cutting methods include flame cutting, plasma cutting, laser cutting, and other methods. During cutting, attention should be paid to protecting the surface of the steel plate from damage and avoiding defects such as cuts or cracks. Heat treatment Heat treatment is an important step in processing formed carbon steel plates. Heat treatment methods include various methods such as normalizing, quenching, and tempering. Heat treatment can enhance the hardness and strength of steel plates, improve the metallographic structure, enhance wear resistance and corrosion resistance, and make carbon steel plates suitable for different usage environments and requirements.

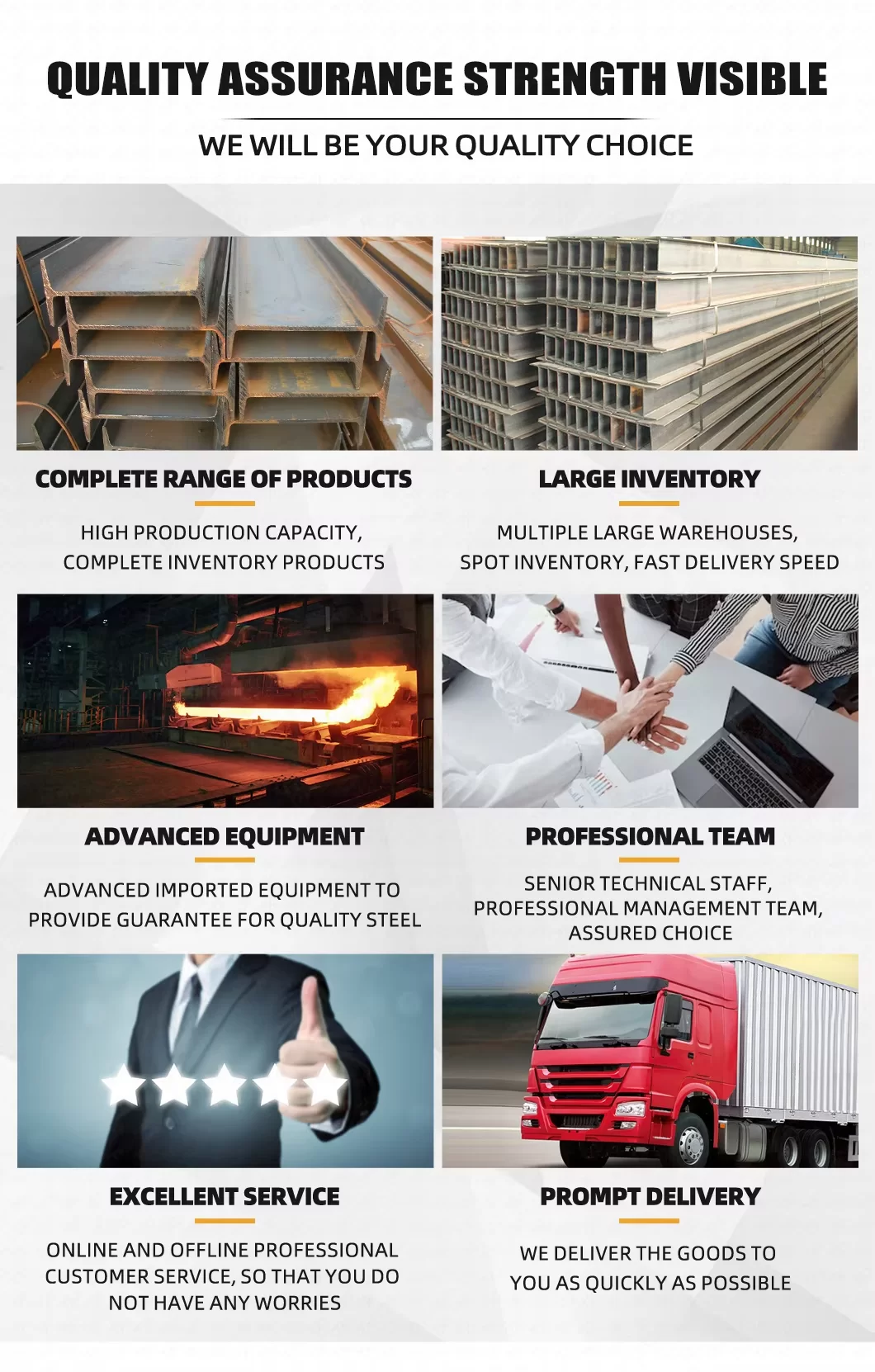

About Us

Our company was founded in 1992 with a registered capital of US$29.8 million. We currently have over 6,000 employees. We are a large-scale, comprehensive steel enterprise integrating coal washing, coking, sintering, ironmaking, steelmaking, rolling, power generation, oxygen production, and scientific research. We have an annual production capacity of 10 million tons each of iron, steel, and materials. Our leading products include high-strength structural steel, steel for boilers and pressure vessels, shipbuilding steel, bridge steel, high-rise building steel, wear-resistant steel, automotive steel, pipeline steel, cold-rolled steel, and galvanized steel.

Delivery & Packaging

Our company's High strength steel plate can be packaged and transported according to customer needs, ensuring quality and quantity. The common size we have long-term inventory and delivery time is very fast.

Automobiles use several types of steel, selected for strength, weight, and corrosion resistance:

Mild Carbon Steel: Used for body panels and structural parts due to its good formability and weldability.

High-Strength Low-Alloy (HSLA) Steel: Provides better strength-to-weight ratio, used in chassis, reinforcements, and safety structures.

Advanced High-Strength Steel (AHSS): Includes dual-phase and martensitic steel, used in safety-critical components like B-pillars and crumple zones. AHSS improves crash resistance while reducing vehicle weight.

Stainless Steel: Used in exhaust systems, trims, and parts exposed to corrosion.

Galvanized Steel: Often used for body panels to prevent rust and increase durability.

Modern automotive design balances strength, weight, and safety. High-strength and advanced steels allow manufacturers to reduce vehicle weight, improving fuel efficiency without compromising crash protection.

Auto grade steel refers to steel specifically engineered for use in the automotive industry. It is designed to meet strict requirements for strength, formability, crash resistance, and corrosion protection, balancing safety, durability, and weight reduction.

Auto grade steel can include:

Mild Carbon Steel: Easy to shape and weld, used for body panels and non-structural parts.

High-Strength Low-Alloy (HSLA) Steel: Stronger than mild steel, used for chassis, reinforcements, and safety components.

Advanced High-Strength Steel (AHSS): Includes dual-phase, martensitic, and TRIP steels, offering superior crash performance and lighter weight, often used in B-pillars, crumple zones, and structural frames.

Galvanized or Coated Steel: Provides corrosion resistance for exposed panels and underbody parts.

In short, auto grade steel is tailored to meet automotive demands, enabling manufacturers to produce vehicles that are safe, lightweight, and durable while also improving fuel efficiency and performance.