Hit enter to search or ESC to close

Q345 is a kind of steel material. It is carbon alloy steel (C<0.2%), good="" overall="" performance="">

Widely used in Bridges, vehicles, ships, buildings, pressure vessels, etc.

Q represents the yield of this kind of material. 345 in the back refers to the yield value of this kind of material, which is about 345MPa. The yield value decreases with the increase of the thickness of the material.

345 Steel Properties and Introduction

Q345 steel is a Chinese GB standard Low Alloy High Strength Structural Steel, material density is 7.85 g/cm3, tensile strength is 470-630 Mpa, and yield strength is 345 MPa (datasheet tested with 16mm diameter steel bars or steel plates). According to GB/T 1591 – 2008, Q345 material has 5 quality grades: Q345A, Q345B, Q345C, Q345D and Q345E. “Q” is the first letter of Chinese Pinyin: “qu fu dian”, which means Yield Point, “345” is short for 345 MPa. For datasheet and specification, please see the tables below.

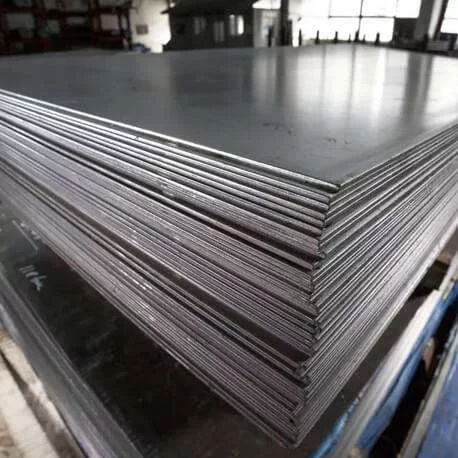

| Product Name | Carbon Steel plate |

| Length | 4m-12m or as required |

| Width | 0.6m-3m or as required |

| Thickness | 0.1mm-300mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled |

| Material | Q345B,Q345C,Q345D,Q345E,Q390,Q390B,Q390C,Q390D, Q390E, Q420,Q420B,Q42OC,Q420DQ420E, Q460, Q460D,Q500C,Q500D,Q500E, Q550C,Q550D,Q550E,Q620C,Q620D,Q620E,Q690A,Q690B,Q690C,Q690D,Q690E,Q690D,Q690C,Q890C,Q890D16Mo3,16MnL, 16MnR ,16Mng, 16MnDR HG785D,S690QL,50MN |

| Application | It is mainly used to make structural parts such as car girder, beam, transmission shaft and car chassis parts, which can reduce the weight of the parts. |

WHY CHOOSE US

We have two 3500mm medium-thick plate lines, one heat treatment and quenching line, one tempering line, one 1250mm hot-rolled coil line, one 650mm medium-width strip line, and one high-speed wire rod line. Our annual production capacity reaches 10 million tons, making us a key plate production base in Hebei Province.

Can you send samples?

What product information do I need to provide?

What are the shipping ports?

About product prices?

What are the certifications for your products?

How long does your delivery time take?

Can I go to your factory to visit?

Does the product have quality inspection before loading?

How to pack the products?

What is your working time?

Steel Plates, Strength That Lasts

High alloy steel and low alloy steel differ mainly in alloy content and properties. High alloy steel contains more than 8% alloying elements, such as chromium, nickel, or molybdenum. This gives it excellent hardness, wear resistance, and corrosion resistance, making it suitable for tools, turbines, and chemical equipment. Low alloy steel has less than 8% alloying elements, often including manganese, silicon, or vanadium. It offers improved strength, toughness, and weldability compared to carbon steel, while being more cost-effective than high alloy steel.

No, low alloy steel is not the same as stainless steel. Low alloy steel contains less than 8% alloying elements, such as manganese, nickel, chromium, or vanadium, which improve strength, toughness, and hardenability. However, its corrosion resistance is limited, so it usually requires protective coatings or surface treatments.

Stainless steel, on the other hand, is a type of high alloy steel with at least 10.5% chromium. The chromium forms a thin, stable oxide film on the surface, giving stainless steel excellent corrosion resistance and making it suitable for food processing, medical instruments, and marine environments.

In short, while both are alloy steels, stainless steel is a high alloy with superior corrosion resistance, whereas low alloy steel focuses on strength and cost-effectiveness.