Hit enter to search or ESC to close

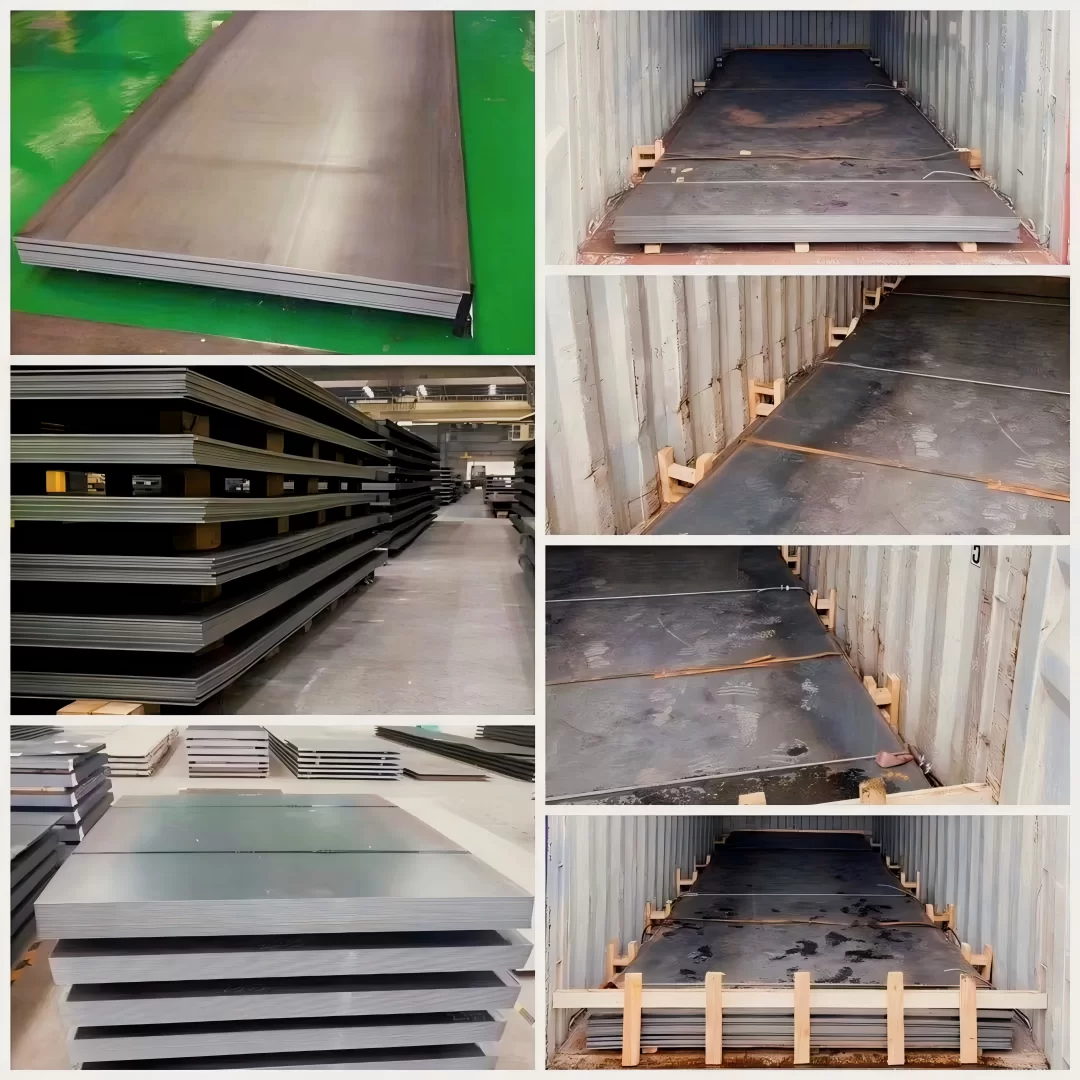

Product descriptions

Q355 Overview

Q355 steel is a low alloy, high-strength steel that is used in welded structures supporting stress and heavy loads. The Q references the yield point, while the number 355 indicates its yield strength. It also replaced Q345.

Uses of Q355

Q355 steel has excellent mechanical properties, great weldability, and ample corrosion resistance. It can be utilized to manufacture and produce petroleum storage tanks, high-pressure vessels, boilers, ships, power stations, and many other high-load structural parts. Q355 is also widely used to make shipping containers, waste storage containers, weather containers, offshore containers, workshop containers, and toolboxes.

Company Profile

Our company was founded in 1992 with a registered capital of US$29.8 million. We currently have over 6,000 employees. We are a large-scale, comprehensive steel enterprise integrating coal washing, coking, sintering, ironmaking, steelmaking, rolling, power generation, oxygen production, and scientific research. We have an annual production capacity of 10 million tons each of iron, steel, and materials. Our leading products include high-strength structural steel, steel for boilers and pressure vessels, shipbuilding steel, bridge steel, high-rise building steel, wear-resistant steel, automotive steel, pipeline steel, cold-rolled steel, and galvanized steel.

The highest quality hot rolled steel is typically hot rolled low alloy high-strength steel or hot rolled mild carbon steel produced under strict quality standards. Among them, ASTM A36 and A572 grades are widely recognized. ASTM A36 is known for its excellent weldability, machinability, and versatility, making it one of the most popular choices in construction. ASTM A572, a high-strength low-alloy steel, offers superior strength and toughness while maintaining good ductility, making it ideal for demanding structural applications.

High-quality hot rolled steel is characterized by uniform thickness, smooth surface finish, consistent mechanical properties, and precise chemical composition. Advanced manufacturing processes, including controlled rolling and cooling, enhance grain structure and improve performance.

In general, the “highest quality” depends on application needs—A36 is best for general use, while A572 and other high-strength low-alloy steels provide better performance for heavy-duty structures. Both are regarded as top standards in hot rolled steel.

The maximum thickness of hot rolled steel depends on the manufacturing process and the type of mill used. Generally, hot rolled steel is produced in thicknesses ranging from about 1.6 mm (1/16 inch) up to 100 mm (4 inches). In specialized heavy plate mills, however, hot rolled steel plates can be manufactured up to 150 mm (6 inches) or even thicker for specific industrial applications.

Hot rolling involves processing steel at high temperatures above its recrystallization point, allowing large sections to be shaped efficiently. This makes it possible to produce very thick plates used in heavy machinery, shipbuilding, pressure vessels, and structural applications like bridges and high-rise buildings.

While extremely thick plates are possible, they require advanced rolling equipment and may be more expensive. For most construction and engineering uses, hot rolled steel plates between 6 mm and 50 mm are the most common. Thus, the maximum thickness typically falls around 150 mm, depending on the mill capacity and steel grade.