Hit enter to search or ESC to close

Product descriptions

API 5L Grade B, also known as L245, is a specific API 5L pipe with a minimum yield strength of 245 MPa (35,500 psi). It is divided into two levels, PSL1 and PSL2, and has four delivery states, R, N, Q, and M. API 5L GR.B is commonly used in oil and gas pipeline transportation systems where pressures are low due to its well-balanced mechanical properties and economic efficiency.

Company Profile

Our company was founded in 1992 with a registered capital of US$29.8 million. We currently have over 6,000 employees. We are a large-scale, comprehensive steel enterprise integrating coal washing, coking, sintering, ironmaking, steelmaking, rolling, power generation, oxygen production, and scientific research. We have an annual production capacity of 10 million tons each of iron, steel, and materials. Our leading products include high-strength structural steel, steel for boilers and pressure vessels, shipbuilding steel, bridge steel, high-rise building steel, wear-resistant steel, automotive steel, pipeline steel, cold-rolled steel, and galvanized steel.

Pipes used in the oil and gas industry must withstand high pressure, temperature, and corrosive environments. Common types include:

Carbon Steel Pipes: Widely used for transporting oil, gas, and water. Grades such as API 5L X42, X52, and X65 offer high strength and durability.

Stainless Steel Pipes: Used in highly corrosive environments, such as offshore platforms or chemical processing, due to excellent corrosion resistance.

Alloy Steel Pipes: Contain elements like chromium, molybdenum, or nickel to improve strength, heat resistance, and corrosion resistance, suitable for high-temperature applications.

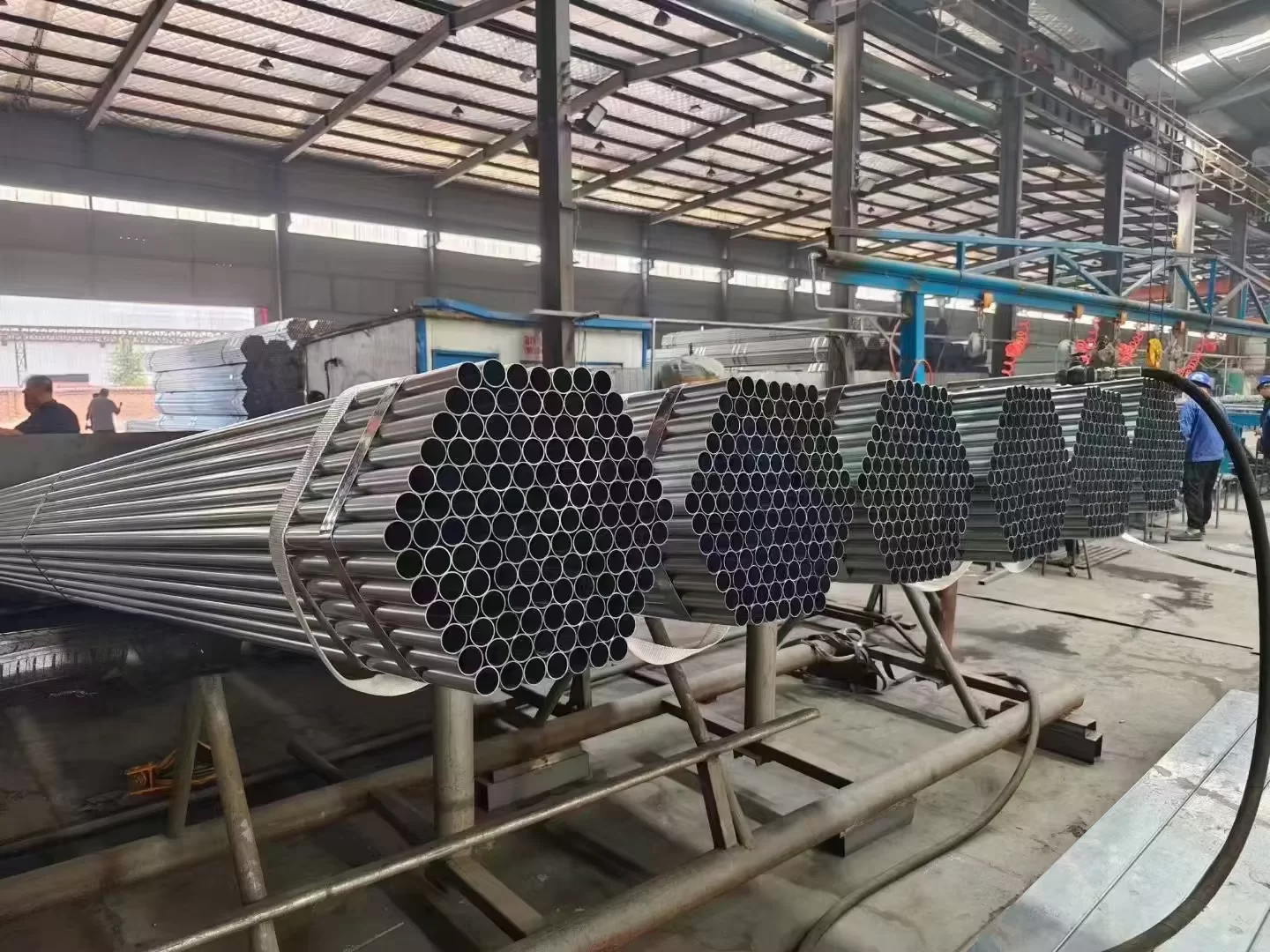

Seamless Pipes: Preferred for high-pressure and critical applications because they have no welded seam, reducing the risk of leaks.

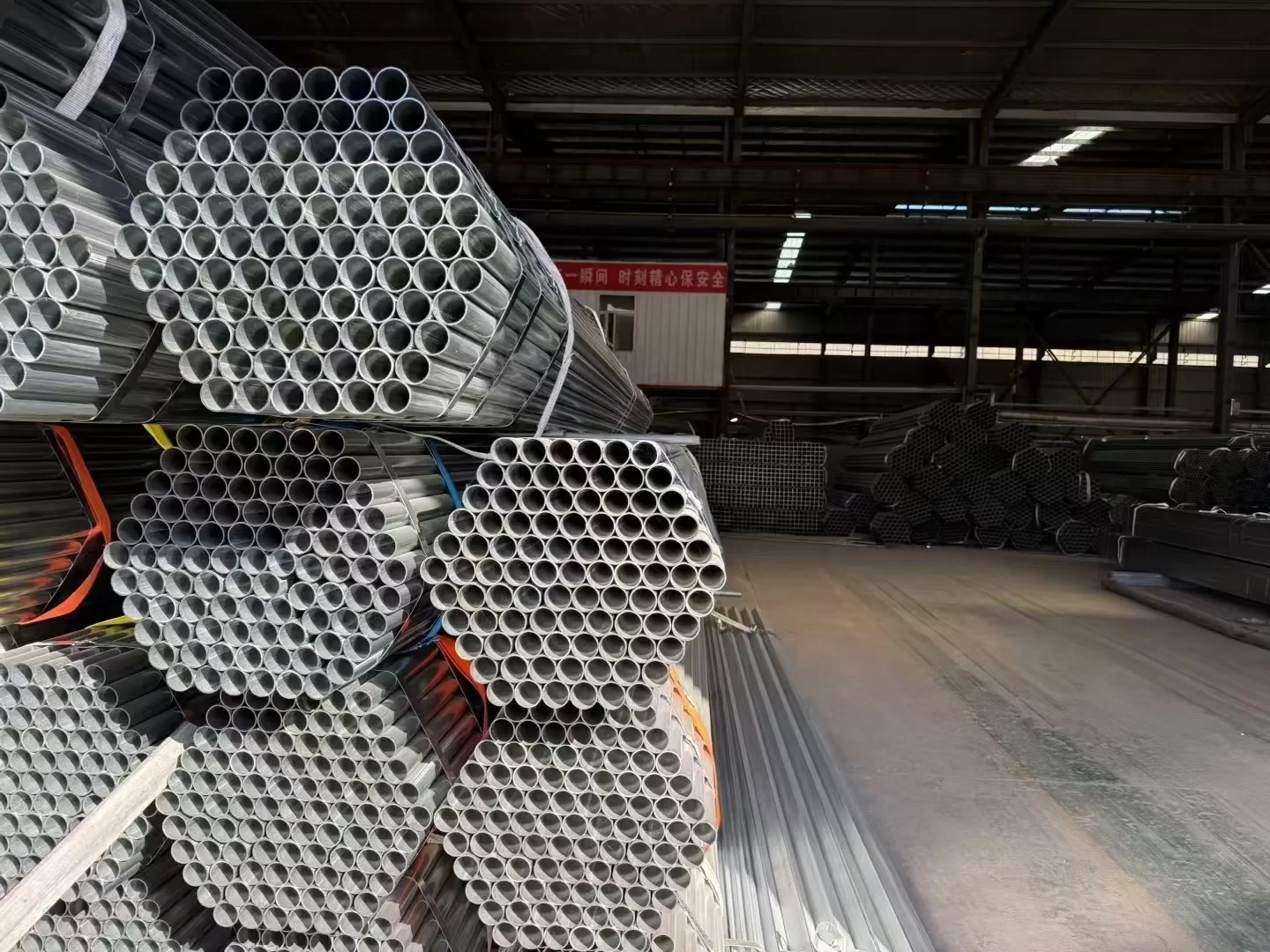

Galvanized or Coated Pipes: Provide additional corrosion protection for pipelines exposed to moisture or harsh environments.

In general, API (American Petroleum Institute) standard pipes are most commonly used in oil and gas for their proven reliability and compliance with industry requirements.

The oil and gas industry primarily uses carbon steel, alloy steel, and stainless steel, selected based on pressure, temperature, and corrosion conditions.

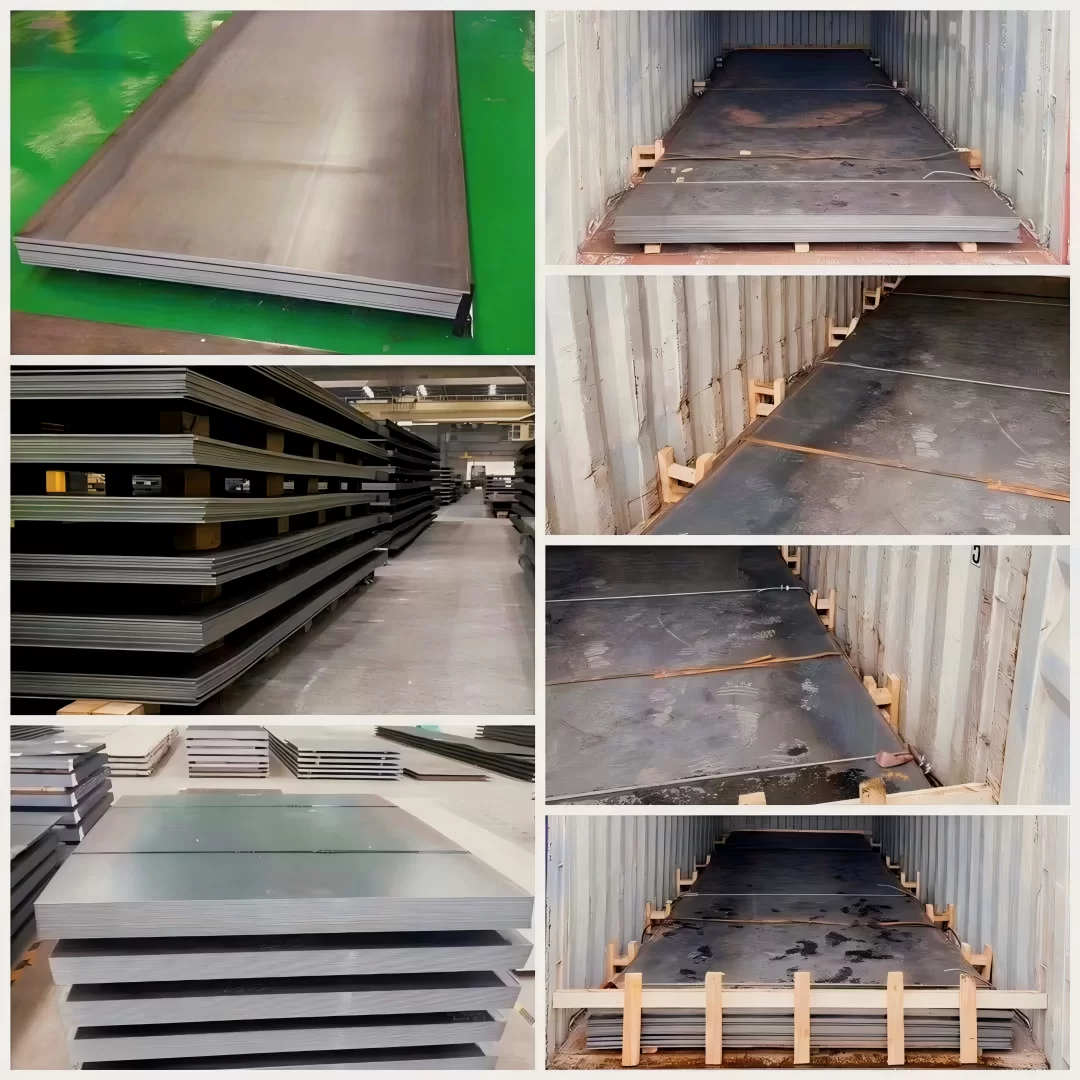

Carbon Steel: Widely used for pipelines and structural components. API 5L grades such as X42, X52, X60, and X65 are common because they provide high strength, toughness, and cost-effectiveness.

Alloy Steel: Contains elements like chromium, molybdenum, and nickel to improve strength, heat resistance, and corrosion resistance, making it suitable for high-pressure, high-temperature (HPHT) applications in drilling and refineries.

Stainless Steel: Austenitic and duplex stainless steels are used in corrosive environments, such as offshore platforms or chemical processing, where resistance to seawater, hydrogen sulfide, or acidic conditions is critical.

Seamless Steel: Often preferred for pipelines and high-pressure equipment due to the absence of welded seams, reducing the risk of leaks.

Overall, the choice depends on mechanical requirements, environmental conditions, and safety standards.