Hit enter to search or ESC to close

Product descriptions

Q345q series steel is low-alloy, high-strength structural steel primarily composed of carbon, manganese, and silicon. It offers excellent toughness, weldability, and high tensile strength while also performing well in low temperatures and resisting atmospheric corrosion.

Naming Rules:

Q: Yield strength.

345: Minimum yield strength of 345 MPa.

q: Suitable for bridge structure.

C/D/E/F: Quality grades. Toughness at 0℃/-20℃/-40℃/-60℃. (e.g. Q345qD)

NH: Weather-resistant, designed to withstand atmospheric corrosion. (e.g. Q345qDNH)

Z-: Z-direction performance grade, such as Z15, Z25. (e.g. Q345qDNHZ15)

It is commonly used in bridge construction, large infrastructure, and structural supports, where its durability and load-bearing capacity are essential for stability in challenging environments.

Characteristics of Q345q Series Steel

High strength, making it suitable for heavy structures.

Reliable performance under stress, reducing the risk of failure.

Good weldability, allowing easy fabrication and assembly.

Excellent toughness, ensuring durability in low temperatures.

Corrosion resistance, extending the lifespan of structures.

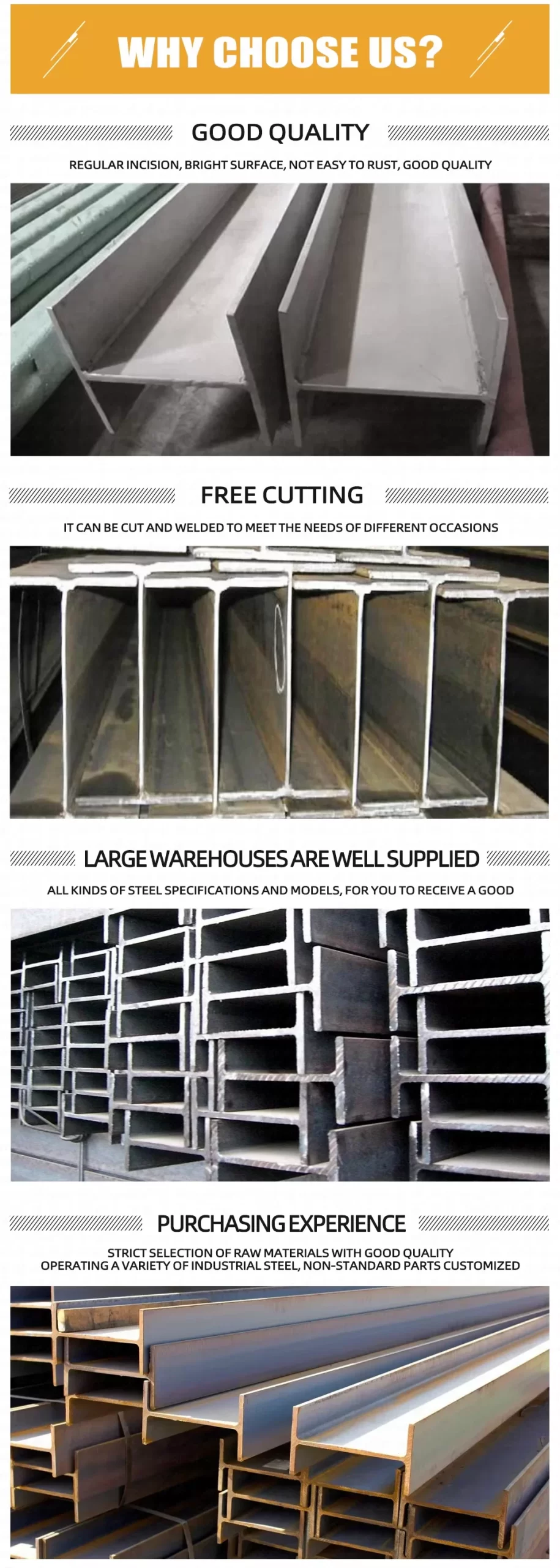

Xingtai Baidy Steel Works Co.,Ltd

The best metal for building a bridge is usually steel, especially structural steel. Steel is widely chosen because of its excellent strength-to-weight ratio, flexibility, and durability. It can handle heavy loads and dynamic forces such as vehicles, wind, and even earthquakes. Unlike brittle materials, steel bends without breaking, making it ideal for long spans and complex designs.

Among steel types, weathering steel (such as Corten steel) is often used for bridges because it forms a protective patina that resists corrosion, reducing maintenance costs. Stainless steel may also be used in specific cases where high corrosion resistance is required, such as in coastal or marine environments.

While aluminum and other metals are lighter, they lack the same strength and fatigue resistance as steel for large structures. Overall, steel remains the best and most practical choice for bridges due to its balance of strength, durability, and cost-effectiveness.

Structural steel typically refers to carbon steel and low alloy steel that are specifically designed for construction applications. The most common type is mild carbon steel, which contains a low percentage of carbon (around 0.05–0.25%). This makes it strong, tough, and highly workable, allowing it to be cut, welded, and shaped with ease.

In addition to carbon steel, low alloy steels with added elements like manganese, vanadium, or chromium are also used. These alloys improve strength, toughness, and resistance to atmospheric corrosion, making them suitable for bridges, towers, and high-rise buildings.

Structural steel is standardized into shapes such as I-beams, H-beams, channels, and angles, providing efficient load-bearing capacity. It is favored because it combines high strength with ductility, ensuring safety under heavy loads and extreme conditions.

Overall, mild carbon steel and low alloy steel are the primary materials classified as structural steel, forming the backbone of modern construction.