Hit enter to search or ESC to close

Product descriptions

| Standard | ASTM EN DIN GB JIS |

| Grade | DX51D+Z、DX52D+Z、S550GD+Z |

| Technique | Cold Rolled Based |

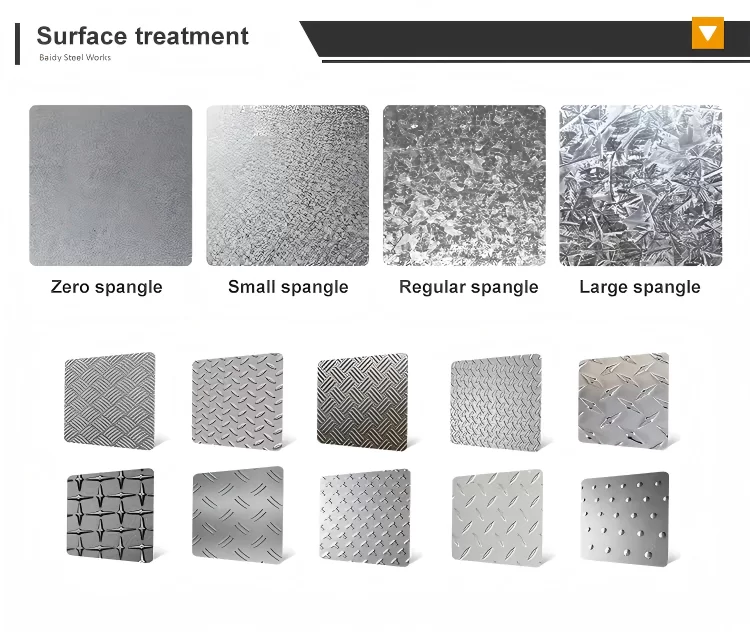

| Galvanized Spangles | Zero spangle / Small spangle / Regular spangle / Large spangle |

| MOQ | 1 Ton |

| Delivery Time | 5-14 days |

| Price Terms | FOB, CRF, CIF, EXW all acceptable |

| Packing | Plastic film + Kraft paper + Strapping + Wooden pallet/Box (Customizable) |

Company Profile

Our company was founded in 1992 with a registered capital of US$29.8 million. We currently have over 6,000 employees. We are a large-scale, comprehensive steel enterprise integrating coal washing, coking, sintering, ironmaking, steelmaking, rolling, power generation, oxygen production, and scientific research. We have an annual production capacity of 10 million tons each of iron, steel, and materials. Our leading products include high-strength structural steel, steel for boilers and pressure vessels, shipbuilding steel, bridge steel, high-rise building steel, wear-resistant steel, automotive steel, pipeline steel, cold-rolled steel, and galvanized steel.

Product packaging

Are you trading company or manufacturer ?

Will you delivery the goods on time?

How can I get your quotation as soon as possible?

Do you accept the third party inspection?

Do you provide samples ? is it free or extra?

The main advantage of using galvanized sheet metal is its excellent corrosion resistance. Galvanization involves coating steel or iron with a layer of zinc, which protects the underlying metal from rust and environmental damage. This makes galvanized sheet metal ideal for outdoor and industrial applications where exposure to moisture, humidity, or corrosive agents is common.

In addition to corrosion protection, galvanized sheet metal offers durability, long service life, and low maintenance requirements. It can be easily cut, bent, and fabricated while maintaining its protective coating. Galvanized steel is widely used in roofing, automotive parts, HVAC systems, construction, and fencing, combining strength with resistance to rust and wear.

Overall, the primary advantage is that it extends the lifespan of steel components, reduces maintenance costs, and provides reliable performance in harsh environments, making it a cost-effective and practical choice for many applications.

Galvanized sheets are used in applications where corrosion resistance, durability, and low maintenance are important. Common uses include:

Construction: Roofing, wall cladding, gutters, and structural components.

Automotive industry: Car bodies, chassis parts, and trailers.

HVAC systems: Ducts, air vents, and ventilation panels.

Agriculture: Silos, fencing, and storage tanks.

Electrical and industrial equipment: Enclosures, cabinets, and machinery parts.

The zinc coating protects the steel from rust, making galvanized sheets ideal for outdoor and humid environments. They are also easy to cut, shape, and weld, which increases their versatility across industries.