Hit enter to search or ESC to close

Product descriptions

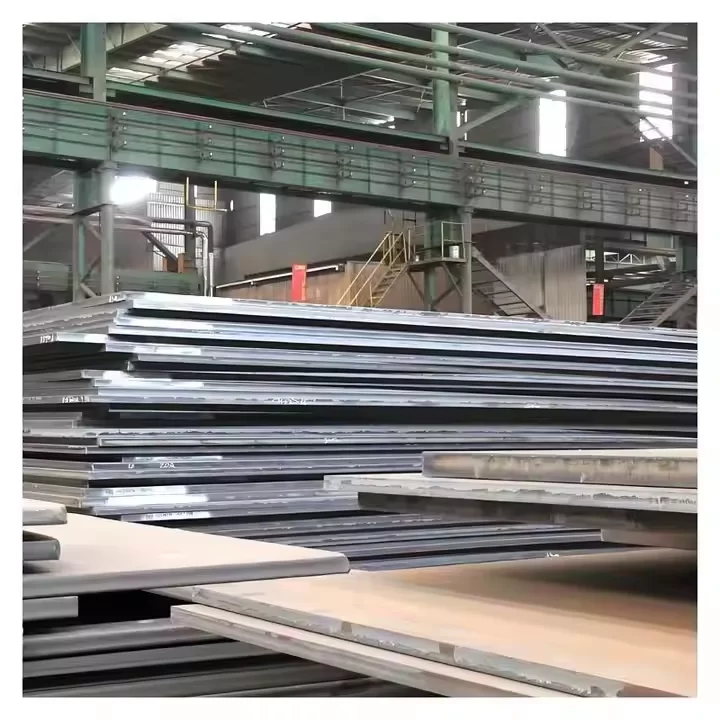

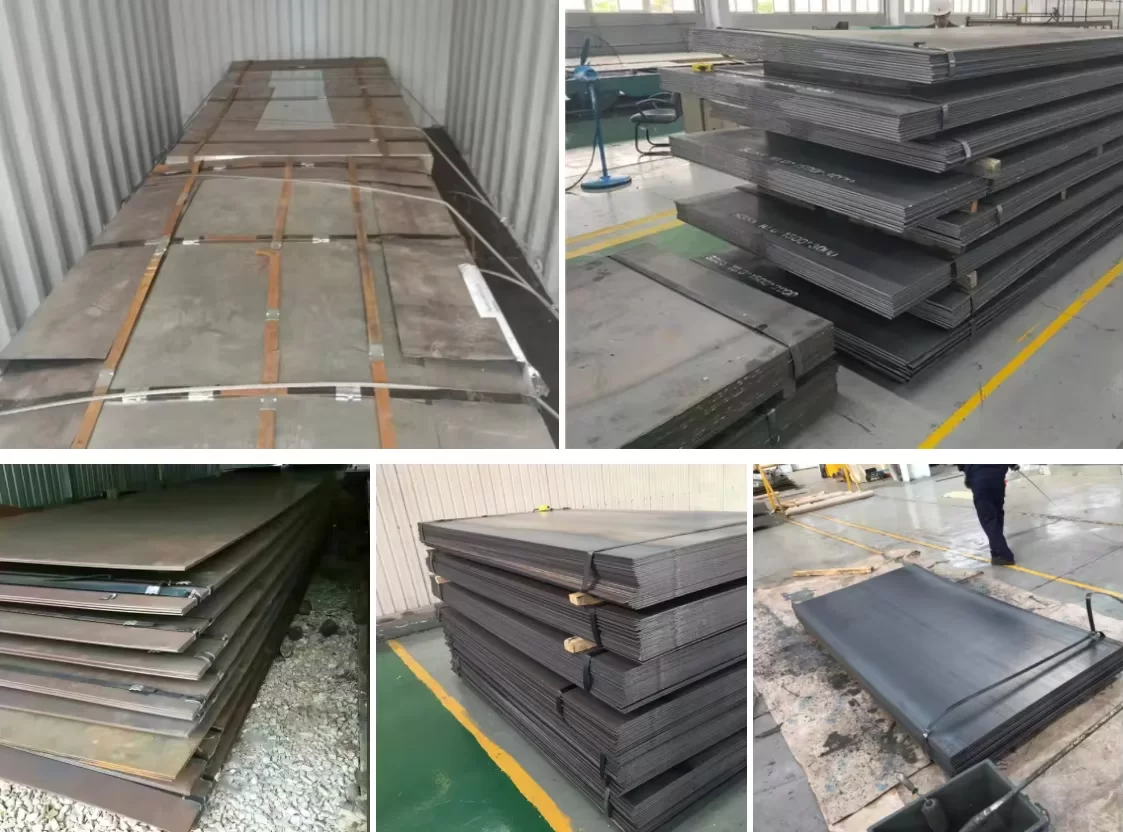

380CL refers to a high-strength low-alloy (HSLA) steel commonly used in the automotive industry, particularly for wheel rims and other structural components. It is a hot-rolled steel coil, known for its good ductility, toughness, and weldability.

Company Profile

Hot rolled steel and cold rolled steel differ mainly in manufacturing process, properties, and applications. Hot rolled steel is produced by rolling steel at high temperatures above its recrystallization point, resulting in thicker, rougher surfaces and less precise dimensions. It is strong, ductile, and cost-effective, making it ideal for structural components, construction, and heavy machinery. Cold rolled steel, on the other hand, is processed at room temperature after hot rolling, which improves surface finish, dimensional accuracy, and mechanical properties such as hardness and strength. It is commonly used in applications requiring smooth surfaces and precise tolerances, like automotive panels, appliances, and metal furniture. While hot rolled steel excels in strength and large-scale structural use, cold rolled steel is preferred when aesthetics, precision, and enhanced strength are important. Both types serve different industrial needs, with cost and performance guiding the choice.

Hot rolled sheet thickness varies depending on the rolling mill and intended application, typically ranging from 1.6 mm (1/16 inch) to around 100 mm (4 inches). In specialized heavy plate mills, thicknesses up to 150 mm (6 inches) or more can be produced for industrial and structural uses. Hot rolling involves processing steel at temperatures above its recrystallization point, allowing thick sheets and plates to be shaped efficiently while maintaining strength and ductility. Thicker sheets are often used in heavy machinery, shipbuilding, bridges, and pressure vessels, while thinner sheets are common in roofing, cladding, and automotive panels. The process produces sheets with slightly rough surfaces and looser dimensional tolerances compared to cold rolled steel, but it is cost-effective for large-scale production. Overall, hot rolled sheet thickness is versatile, meeting both structural and industrial requirements depending on the project’s scale and strength needs.