Hit enter to search or ESC to close

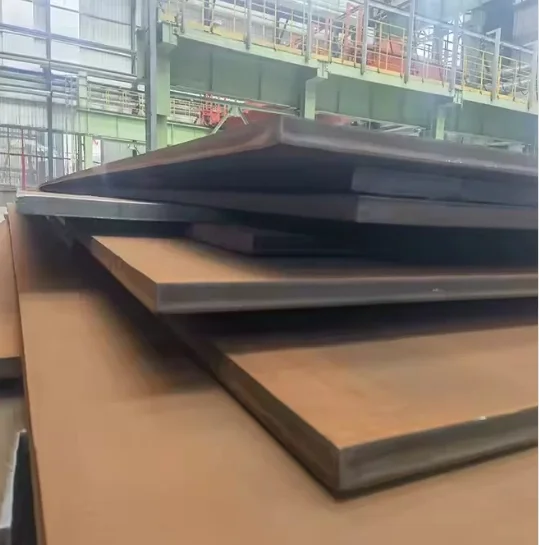

In the symphony of modern infrastructure development, the humble yet mighty construction steel plate plays an undeniably pivotal role, often serving as the unsung hero beneath the grandeur of our skylines and the resilience of our bridges. Far from being a mere commodity, these specialized plates are the very sinews and bones of structural integrity, foundational to virtually every major building, bridge, and industrial complex erected today. The global demand for structural steel in construction is projected to exceed 160 million metric tons annually by 2027, with a significant portion comprising various grades of steel plates. This growth is fueled by an accelerating pace of urbanization, relentless innovation in architectural design, and an increasing emphasis on resilient and sustainable building practices worldwide. From the deep foundations of towering skyscrapers to the expansive decks of critical transport infrastructure, and from the robust frameworks of manufacturing plants to the protective enclosures of energy facilities, construction steel plates provide the unparalleled strength, durability, and flexibility that engineers and architects demand. Their ability to withstand immense loads, resist environmental stresses, and offer predictable performance under diverse conditions makes them irreplaceable. This article delves into the profound impact and sophisticated engineering that define these essential materials, exploring their technical advantages, diverse applications, and the custom solutions that drive the construction sector forward.

Modern construction steel plates are not simply "metal sheets"; they are products of advanced metallurgy and precision manufacturing, engineered to meet stringent performance criteria. Their technical superiority stems from a combination of inherent material properties and sophisticated processing techniques. Firstly, the hallmark of structural steel plates is their exceptional strength-to-weight ratio. This allows for lighter designs without compromising structural integrity, reducing material costs, foundation requirements, and overall construction timelines. For instance, high-strength low-alloy (HSLA) steels, commonly used as construction steel plates, offer yield strengths far exceeding that of conventional carbon steels, enabling thinner sections to carry equivalent loads. Secondly, their superb weldability is a critical advantage. Advanced steel compositions are designed to be easily welded without extensive preheating or post-weld treatment, facilitating complex fabrications and on-site modifications, thus speeding up project completion and ensuring seamless structural continuity. Furthermore, ductility – the ability of the material to deform under tensile stress without fracturing – is paramount in seismic zones, allowing structures to absorb energy during an earthquake without catastrophic failure. Steel plates are manufactured with carefully controlled chemical compositions and microstructures to optimize this property. Beyond these, modern steel plates can be treated for enhanced corrosion resistance, fire resistance, and impact toughness, through alloying elements or specialized coatings, extending their service life and ensuring safety in extreme environments. The relentless pursuit of improved mechanical properties, combined with increasingly efficient production methods, positions construction steel plates as an indispensable and evolving resource for the future of construction.

The vast array of construction steel plates available today necessitates a deep understanding of their specific grades, governing standards, and performance benchmarks to make informed material selections. Each grade is meticulously engineered for particular applications, balancing factors such as strength, weldability, formability, and resistance to environmental factors. For example, ASTM A36 is a widely recognized carbon structural steel, offering good strength (minimum yield strength of 250 MPa) and excellent weldability, making it suitable for general construction purposes like building frames and bridges. For more demanding applications, steels conforming to ASTM A572 Grade 50 (minimum yield strength of 345 MPa) or European standard EN 10025 S355J2 (minimum yield strength of 355 MPa with enhanced impact toughness at -20°C) are often specified. These higher-strength grades allow for optimized designs with reduced material usage and lighter overall structures, particularly beneficial for long-span bridges, heavy-load bearing components, and critical infrastructure. Beyond base mechanical properties, designers must also consider impact toughness, especially for structures exposed to low temperatures or dynamic loading, where brittle fracture is a concern. Fire resistance, fatigue resistance, and even aesthetic considerations (for exposed structural elements) can also influence grade selection. Adherence to international standards (ASTM, EN, JIS, ISO) is not just a regulatory compliance measure but a guarantee of consistent quality, predictable performance, and interchangeability across global projects. Understanding the nuances of these specifications allows engineers to optimize design, ensure safety, and achieve cost-effectiveness by selecting the most appropriate construction steel plates for each unique structural challenge.

Choosing the right supplier and grade of construction steel plates is a critical decision that impacts a project's budget, timeline, and long-term performance. While specific manufacturer names are often proprietary information or vary by region, we can illustrate the comparative factors by examining different steel grades and hypothetical offerings that might be supplied by leading global manufacturers. This comparison highlights key performance indicators that project managers and engineers typically evaluate when procuring steel plates. These metrics include yield strength (the stress at which the material begins to deform permanently), tensile strength (the maximum stress the material can withstand before breaking), impact toughness (resistance to fracture under sudden load, often tested at specific low temperatures), and the typical applications for which each grade is best suited. Certifications are also paramount, ensuring that the plates meet recognized international quality and safety standards. Below is a comparative table illustrating these critical differences across common construction steel plate grades:

Grade/Type | Min. Yield Strength (MPa) | Tensile Strength (MPa) | Min. Impact Toughness (J @ °C) | Key Application Areas | Common Certifications |

ASTM A36 | 250 | 400-550 | N/A (room temp ductility) | General structural applications, building frames, bridge components, non-critical parts. | ASTM A36 |

ASTM A572 Grade 50 | 345 | 450-620 | 20 J @ 0°C (optional) | High-rise buildings, bridges, transmission towers, heavy construction equipment. | ASTM A572 |

EN 10025 S355J2 | 355 | 470-630 | 27 J @ -20°C | Critical structures, offshore platforms, infrastructure in cold climates, heavy machinery. | EN 10025-2 |

API 2H Gr.50 (Normalized) | 345 | 485-620 | 34 J @ -40°C | Offshore structures, oil and gas platforms, demanding marine environments. | API 2H |

This table underscores the importance of aligning the specific needs of a project with the precise capabilities of different steel plate grades. While A36 offers cost-effectiveness for general use, projects demanding superior strength, cold weather performance, or extreme environmental resistance will necessitate grades like A572 Gr.50, S355J2, or even specialized offshore grades like API 2H Gr.50. Manufacturers often differentiate themselves through consistency in quality, speed of delivery, availability of niche grades, and the extent of value-added services such as cutting, forming, and surface treatment. A thorough evaluation of a supplier's mill certifications, quality control processes, and past project performance is crucial for mitigating risks and ensuring the long-term success of any construction endeavor.

The complexity and unique requirements of modern construction projects rarely allow for a one-size-fits-all approach to steel plates. This is where the ability to provide customized solutions becomes invaluable, transforming raw material into precisely engineered components ready for integration. Leading suppliers offer an extensive range of fabrication services, leveraging advanced technology to meet even the most intricate design specifications. Customization typically begins with cutting. Whether it's intricate shapes for architectural aesthetics, large blanks for shipbuilding, or precise components for heavy machinery, various cutting techniques are employed. High-definition plasma cutting offers speed and precision for thicker plates, while laser cutting provides unparalleled accuracy and a clean edge for thinner materials. Oxy-fuel cutting is often used for very thick sections where speed is critical. Beyond cutting, plates can be formed through bending, rolling, or pressing to create curved sections, cones, or other complex geometries required for tanks, pressure vessels, or specialized architectural elements. Drilling, punching, and welding services further refine these components, preparing them for seamless assembly on-site. Surface treatments, such as grit blasting and primer application, are also common customization options, providing immediate corrosion protection and optimal surfaces for subsequent coatings. For example, a bridge project might require a supplier to cut and pre-drill high-strength steel plates for girders, then apply a specialized primer suitable for marine environments, all before delivery. This level of customization significantly reduces on-site labor, improves construction efficiency, minimizes waste, and ensures that every steel component arrives precisely as specified, contributing to the overall integrity and longevity of the structure.

The versatility and strength of construction steel plates are best evidenced by their ubiquitous presence across a vast spectrum of real-world applications, each demanding specific properties and contributing to the functionality and safety of our built environment. Consider the iconic infrastructure of long-span bridges: high-strength steel plates form the backbone of their massive girders, orthotropic decks, and cable anchorages, designed to carry immense traffic loads and withstand dynamic forces, often employing grades like ASTM A709 Gr. 50W (weathering steel) for reduced maintenance. In the realm of high-rise commercial and residential buildings, steel plates are fundamental to fabricating structural frames, shear walls, and core bracing, providing the necessary rigidity against wind and seismic forces while allowing for large open-plan interiors. Offshore oil and gas platforms are another prime example, where specialized marine-grade steel plates (e.g., API 2H/2W grades) are engineered for exceptional toughness and fatigue resistance in extremely corrosive and high-stress ocean environments, forming the legs, decks, and modules that support drilling operations. For industrial facilities, such as power plants, chemical processing plants, and heavy manufacturing units, steel plates are crucial for constructing robust equipment foundations, storage tanks, pressure vessels, and large-diameter piping systems, often requiring materials with specific high-temperature or corrosion-resistant properties. Even in the realm of pre-engineered buildings and modular construction, standardized steel plates are cut and fabricated into beams, columns, and wall panels off-site, drastically accelerating construction timelines and ensuring consistent quality. These diverse applications underscore the critical importance of selecting the appropriate grade and ensuring precise fabrication of construction steel plates to guarantee the performance, safety, and longevity of vital structures worldwide.

As the global construction industry increasingly prioritizes sustainability, the role of construction steel plates becomes even more pronounced, reflecting a commitment to environmental stewardship and long-term economic viability. Steel is one of the most recycled materials globally, boasting an exceptionally high recycling rate that significantly reduces the demand for virgin resources and minimizes waste. Modern steel production processes are also becoming progressively more energy-efficient, with advancements in electric arc furnaces (EAFs) using recycled scrap steel requiring substantially less energy than traditional blast furnaces. Furthermore, the inherent durability and longevity of steel structures translate into reduced maintenance and replacement cycles, further contributing to a lower lifetime environmental footprint. The ability of construction steel plates to be designed for optimized material use, coupled with their high strength-to-weight ratio, means that less material is often needed to achieve desired structural performance compared to other materials. This not only conserves resources but also reduces transportation emissions. Innovations in steel metallurgy continue to push boundaries, leading to the development of new grades with enhanced properties that allow for even lighter, more efficient designs. From embodying the principles of a circular economy through extensive recycling to enabling resilient and energy-efficient structures, construction steel plates are at the forefront of sustainable building practices. Their enduring strength, adaptability, and environmental credentials ensure that they will remain a cornerstone of construction, shaping a more sustainable and robust future for generations to come. The continued investment in advanced manufacturing and material science promises an even greener horizon for these essential components of our built world.

· Q1: What are the primary types of construction steel plates used in building?

A1: The primary types include carbon structural steel plates (e.g., ASTM A36, EN S235, S275) for general applications, high-strength low-alloy (HSLA) steel plates (e.g., ASTM A572 Gr. 50, EN S355) for higher strength requirements, and sometimes weathering steel plates (e.g., ASTM A588, A709 Gr. 50W) for structures exposed to atmospheric conditions without painting.

· Q2: How do I select the correct grade of steel plate for my project?

A2: Selection depends on several factors: the required yield and tensile strength, environmental conditions (temperature, corrosion risk), loading conditions (static, dynamic, seismic), fabrication requirements (weldability, formability), and specific project specifications or building codes. Consulting with a structural engineer is highly recommended.

· Q3: What are common fabrication services offered for construction steel plates?

A3: Common services include various cutting methods (plasma, laser, oxy-fuel), bending, rolling, drilling, punching, welding, and surface treatments like blasting and priming to prepare the plates for installation and prevent corrosion.

· Q4: Are construction steel plates sustainable?

A4: Yes, steel is one of the most sustainable construction materials. It is 100% recyclable without loss of properties, leading to a high recycling rate globally. Its durability ensures long service life, and modern production methods are increasingly energy-efficient.

· Q5: What certifications should I look for when purchasing construction steel plates?

A5: Look for mill certificates (MTCs) that conform to international standards such as ASTM, EN (European Norms), JIS (Japanese Industrial Standards), or ISO. These certificates confirm the plate's chemical composition, mechanical properties, and compliance with the specified grade.

· Q6: How does impact toughness affect steel plate selection for construction?

A6: Impact toughness is crucial for structures exposed to low temperatures or dynamic/impact loads, preventing brittle fracture. Plates with specified minimum Charpy V-notch (CVN) impact values (e.g., EN S355J2 at -20°C) are chosen for such applications to ensure structural integrity under adverse conditions.

· Q7: Can construction steel plates be customized for unique architectural designs?

A7: Absolutely. With advanced cutting technologies like laser and high-definition plasma, steel plates can be precisely cut into intricate shapes and profiles. They can also be bent, rolled, and formed to create curved or complex architectural elements, offering significant design flexibility.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.